Design and product development

Design and production combines mechanical and plant engineering with state-of-the-art electronics. In addition there is sophisticated measuring and control technology as well as information technology. This results in completely new products and processes with which you can efficiently test mechatronic components and parts.

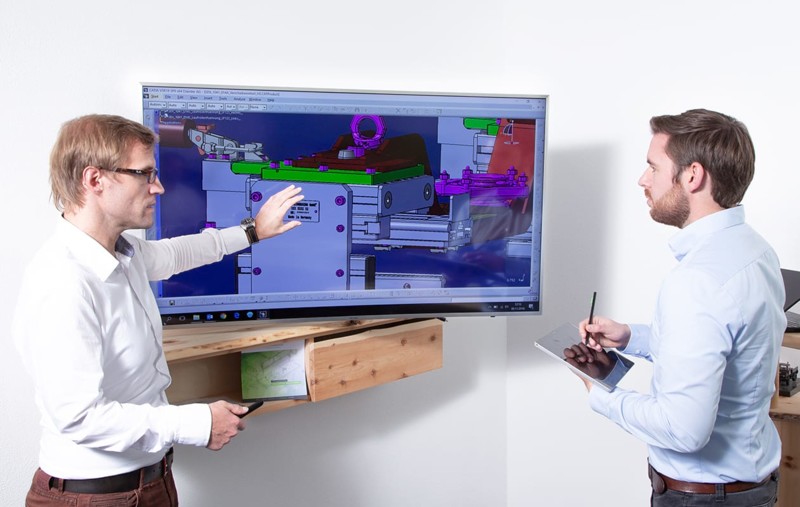

DESIGN SERVICES

Our experts will design tools, test systems and precise devices with computer-assisted technology. We use different CAD systems such as CATIA, Siemens NX, CREO Parametrics or Solid Works Professional.

We align the system our specialists work with according to your wishes. If necessary, we will convert your data from CATIA V4 to V5. This saves you time and allows you to concentrate on your core business.

VEHICLE DEVELOPMENT INTERIOR

Interior components

From the first idea to the start of batch production: Our experts develop systematic concepts, construct and produce prototypes – and verify them through finite element simulation. In advanced project phases they support and supervise toolmaking. By combining the hardware and software development, we produce high quality interior components.

Example projects:

- HMI components for luxury vehicles

- Centre consoles with integrated controls

- Ergonomic studies and seating boxes

- Multi-direction joystick with integrated screen

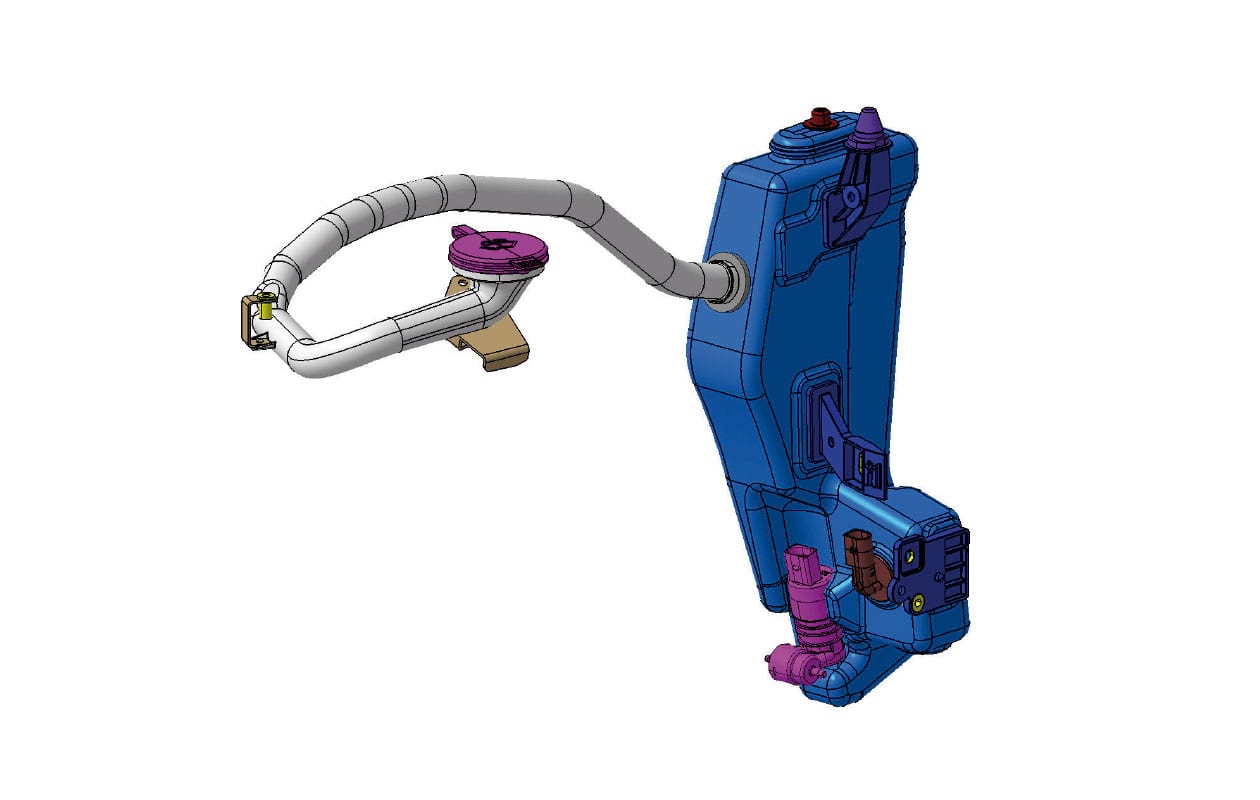

COMPONENT DEVELOPMENT

Sub-assembly holders in the drive train

Air ducts, holders, containers and covers: We develop individual applications for the ancillary components in the drive train. You benefit from state-of-the-art production technologies – from plastic injection and light metal die casting to sheet metal forming and fibre lamination.

Example projects:

- Wiping water tank in blow moulding technology

- Air ducts for cooling modules

- Holder for HVAC components

- Air ducts for brake cooling

- Bag bellow conduits

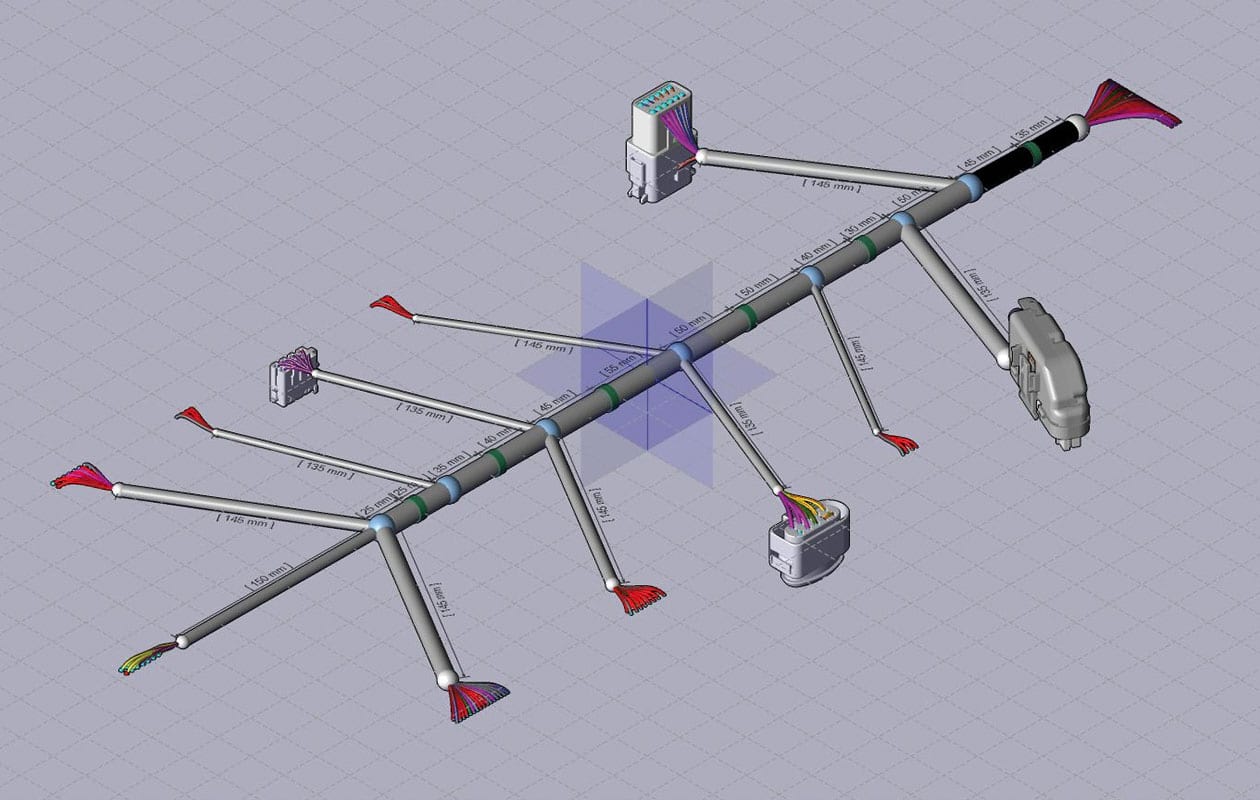

WIRING SET AND CABLE HARNESS DEVELOPMENT

3D and 2D installations, fixings and seals: We develop cable harnesses in a wide variety of installation spaces – precisely tailored to your needs.

Parallel to the installation in the space, the wiring harness is filled with all the electrical information. We process a wide variety of circuit diagram formats, up to signal and wiring lists and create all documents such as nail board drawings, cable lists and parts lists together with you.

Do you need a special solution - holders, channels or plugs? We develop innovative mechanical components for you.

Take advantage from the holistic service from a single source: in our in-house production, we handle all the steps involved in wiring set and cable harnessing and develop your products right through to the series-ready wiring harness.

Example projects:

- Adapter cable with in-house development of the connector

- Cable set for measuring and control cabinets

- On-board network of an electric minibus

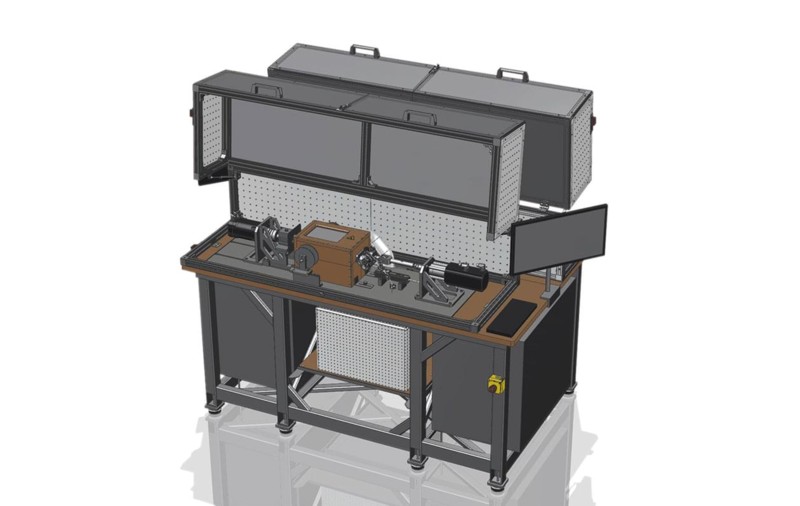

COMPONENT TEST STANDS

Our experts design and manufacture development and simulation test benches for you, with which you can test your components for their function and service life under realistic conditions. This allows you to ensure your quality sustainably. Our specialists design suitable test systems for your various components, precisely following your requirements.

For example, we integrate variable factors such as temperature, dynamics and pressure as well as the statics in the test system. This allows you to test your machines and systems successfully under different conditions.

Example projects:

- Test benches for ball screw drives

- Hydraulic pumps

- Bicycle dampers

- Roller bearings

- Starters

MODERNISING AND CERTIFYING TEST STANDS

Extend or convert your existing test benches with our experts. This way you can increase your range of test parts – from design through production to assembly and commissioning.

In addition, we modify your test benches according to Machinery Directive 2006/42/EC - for more safety at the workplace. To do this, our mechanical engineering professionals define and develop security measures and implement them successfully for you. All changes are technically recorded and documented – for your CE certification.

Example projects:

- Design of secured enclosures for test benches

- Modernisation of engine simulation test benches for starter generators

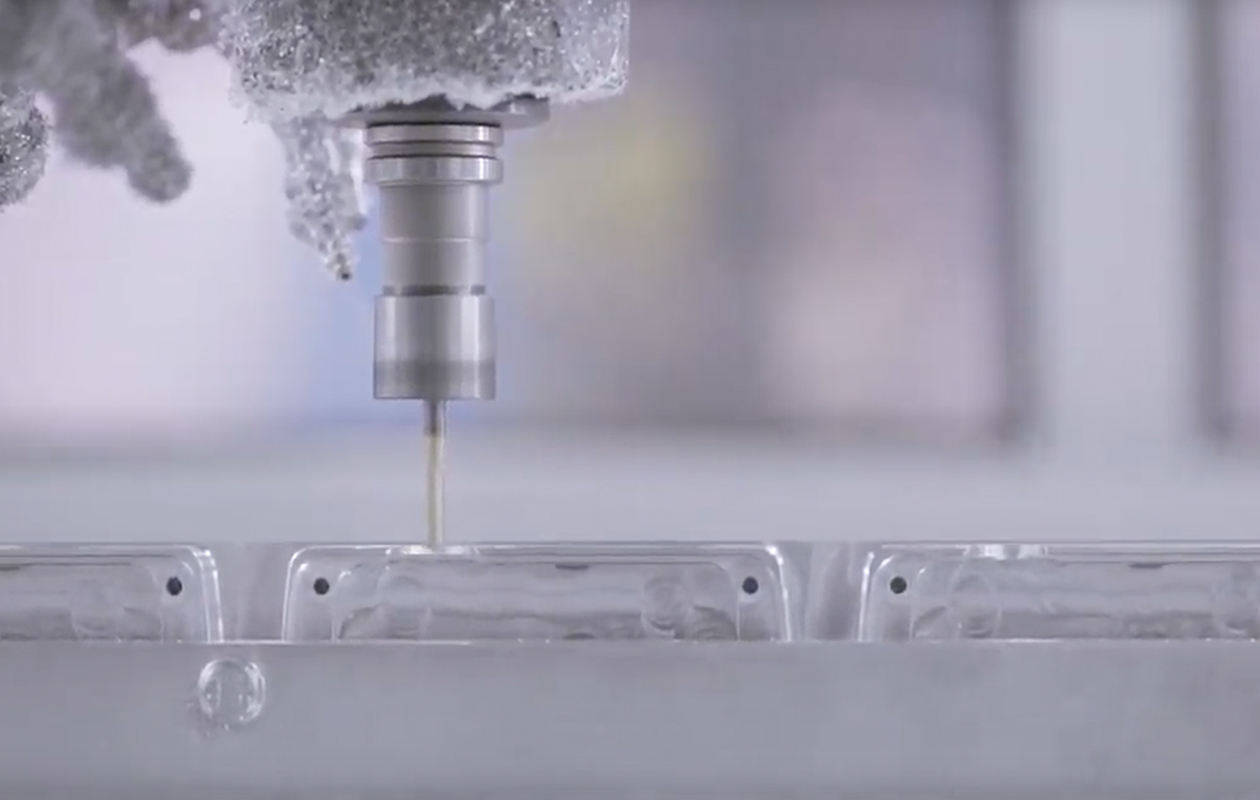

DEVICE AND SPECIAL TOOL MANUFACTURING

Our specialists design and manufacture special devices for you, with which you can assemble components and assemblies simply and safely. In addition, we develop practical tools for your assembly, testing and production process. We have an individual, flexible approach towards your specific requirements.

Example projects:

- Pivot installation for mounting control units

- Positioning device for measurement application

- Special tools for gluing oil filters or leak tests

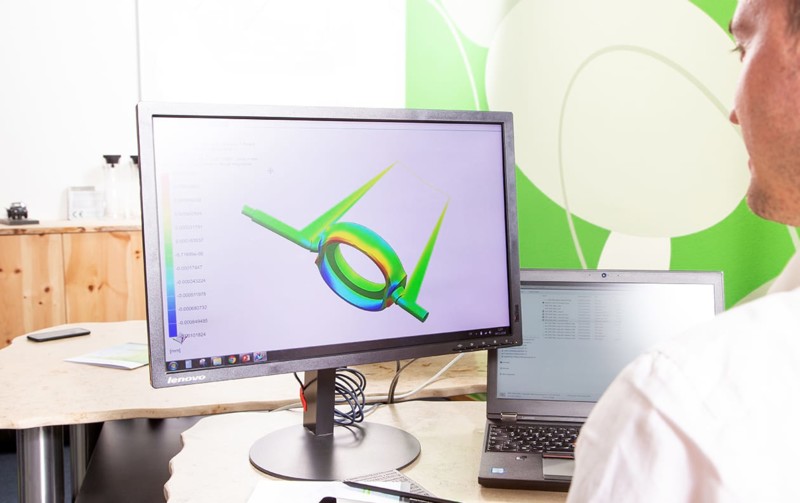

SIMULATION, CALCULATION, DMU SPACE STUDIES

To accompany your project, our engineering experts calculate the strength and vibration of your components and assemblies. We also examine the digital installation and removal for you, and check collision and packaging aspects.

Thanks to small but decisive changes to the design, we ensure the buildability for you and so ensure that the components are optimally designed – in the entire product development process.

TEST BENCH ADAPTATIONS

Our experts design and build customised adaptation parts and sub-assemblies for your existing inspection systems - and integrate them for you. This saves you time and costs: For example, you can reduce set-up time or test new samples without much effort. This makes your test procedure more flexible.

Example projects:

- Adaptations for passive safety

- Trolley systems for engine test stands

- Test rigs

- Test specimen fixtures

- Change parts

DIGITAL TWIN AND VIRTUAL REALITY (VR)/AUGMENTED REALITY (AR)

Over the complete lifespan, our experts map real machines or equipment virtually with a digital twin. This is how we accompany your products holistically – from the first idea through the entire, optimised life cycle.

Sensors on your machines continuously supply data and information to the virtual clone. This allows the digital twin to keep learning – for example, to react independently and to compensate for, or correct, errors. This helps us to optimise your system design and shorten your changeover times. You put your machines into operation even more efficiently, use them without errors – and bring future products to an even higher level of quality.

At the same time, our experts work out analysis and interaction models for you with the digital twin, which you can test on all standard output media. For example, you can try out different test quantities under virtual conditions and derive important information for your real products. In a VR session, for example, you can look at a product realistically via an interaction model. You can do this independent of time and place. Or you can integrate the digital twin in real environments using augmented reality (AR) or 3D scanning and gain valuable insights.

SERVICE & MAINTENANCE

Our experts also look after you when it comes to after sales service: They analyse your machinery and equipment and pro-actively maintain it to minimise, or even prevent, downtime. Keyword: Predictive Maintenance. This extends the life of your machines and saves costs.

Would you like to perform service and maintenance work yourself? Here, too, our experts will be glad to support you and provide you with practical instructions and documentation.

TRADE SHOW EXHIBITS

Our experts give your successful trade show appearance the perfect stage: They design trade show exhibits that exactly match your goals and wishes.

Whether you want a simple or complex design: Starting with the idea, right through to the finished trade show exhibit, our specialists construct your exhibit in 3D using state-of-the-art CAD software, manufacture it, assemble it, put it into operation and test that it is functioning properly.

This helps you organise your trade show exhibits in a time- and cost-saving way - and inspire your visitors.