Mechanical Engineering

Mechanical engineering combines machine and plant construction with state-of-the-art technology. This includes sophisticated measuring, control and regulating technology as well as information technology, resulting in entirely new products and processes with which you can efficiently test mechatronic components and parts. For more quality, smooth functionality and a long service life.

CONSTRUCTION SERVICES

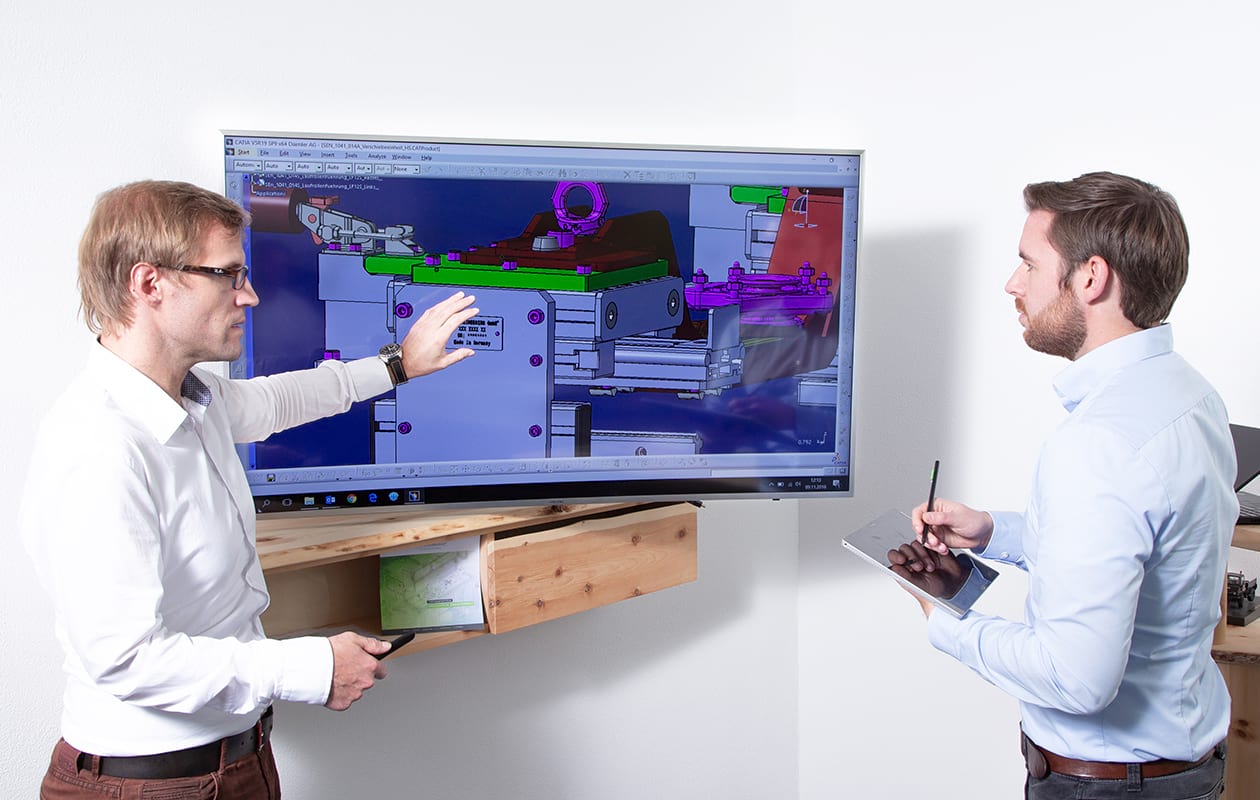

The experts from the STAR Engineering department will design tools, test systems and bespoke equipment for you using computer-aided technology. To do this, we use various CAD systems such as CATIA, Siemens NX, CREO Parametrics or Solid Works Professional.

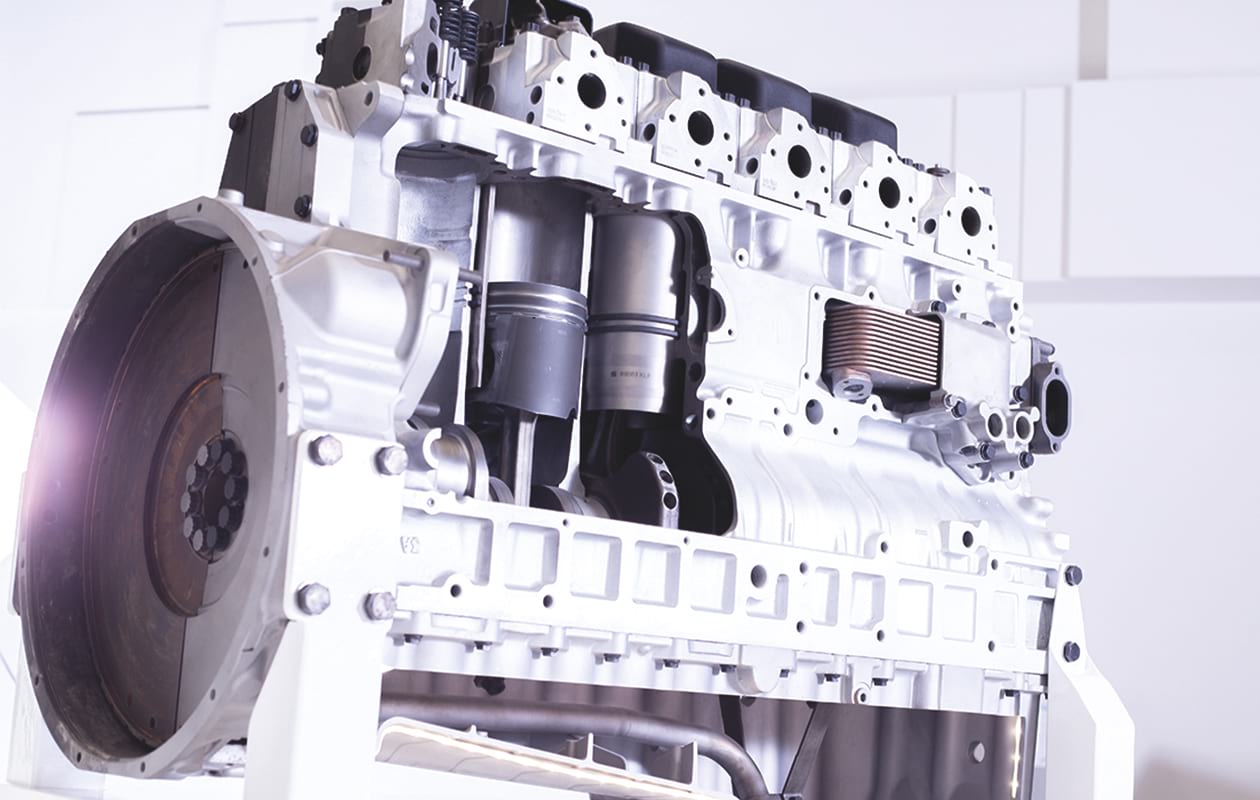

COMPONENT TEST BEDS

Our experts design and produce development and simulation test beds for you with which you can test the function and service life of your components under realistic conditions. You can thus ensure long-lasting quality. During this process, our specialists design suitable testing systems for each of your various components and tailor them precisely to your needs.

For example, we integrate variable factors such as temperature, dynamics and pressure as well as static in the testing system. This means you can successfully test your machines and plants under various conditions.

Example projects:

- Test beds for ball screws

- Hydraulic pumps

- Bicycle dampers

- Rolling bearings

- Starters

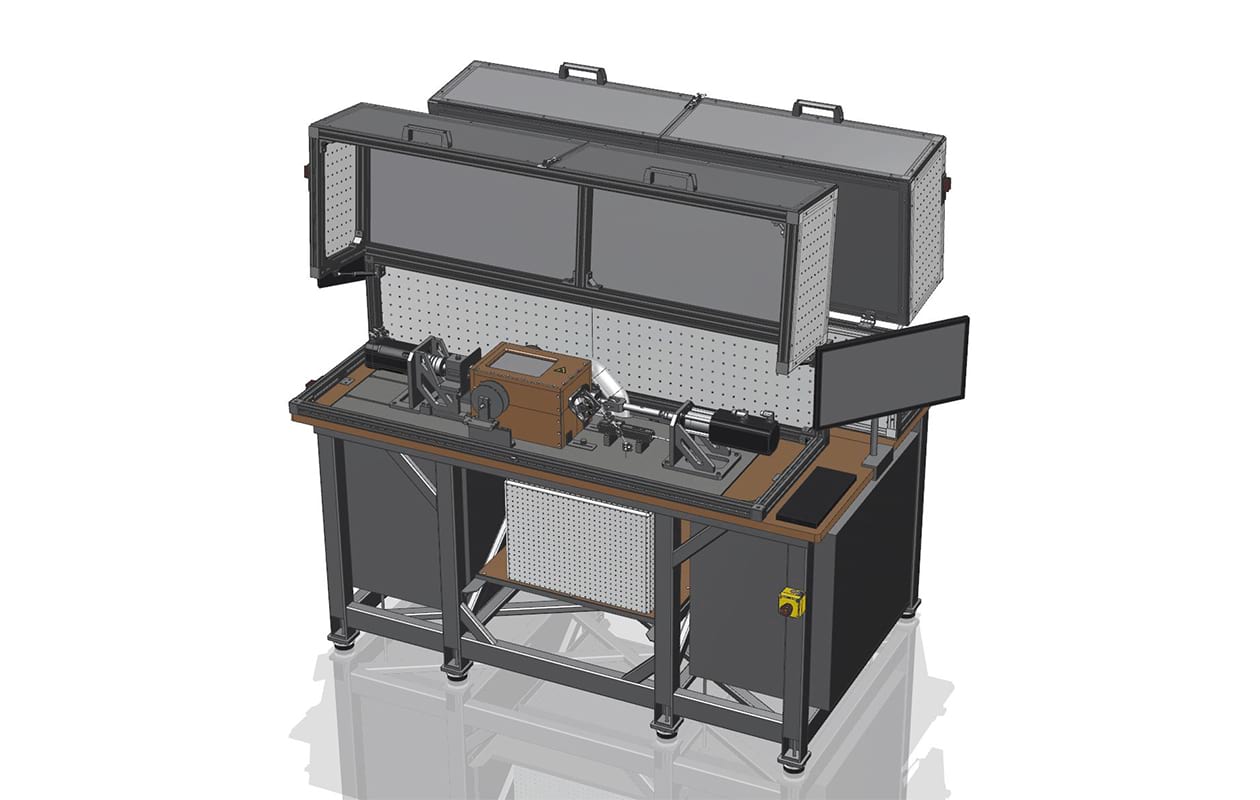

MODERNIZE AND CERTIFY TEST BEDS

Expand your existing test beds or custom modify them with the aid of our experts. You can therefore expand your test piece range – from design and production to installation and commissioning

In addition, we modify your test beds in

accordance with the Machinery Directive 2006/42/EC – for more safety in the

workplace. To do this, our mechanical engineering professionals define and

develop security measures and successfully implement these for you. All

modifications are technically documented and verified – for your CE

certification.

Example projects:

- Construction of secured housing for test beds

- Modernization of motor simulator test beds for starter generators

DEVICE CONSTRUCTION AND SPECIAL TOOL CONSTRUCTION

Our specialists design and produce special devices for you with which you can easily and safely install components and modules. In addition, we develop practical tools for your installation, testing and production process. To this end, we cater to your specific requirements in a flexible and individual manner.

Example projects:

- Swivel device to install control units

- Positioning device for measurement applications

- Special tools to affix oil filters or for leakage tests

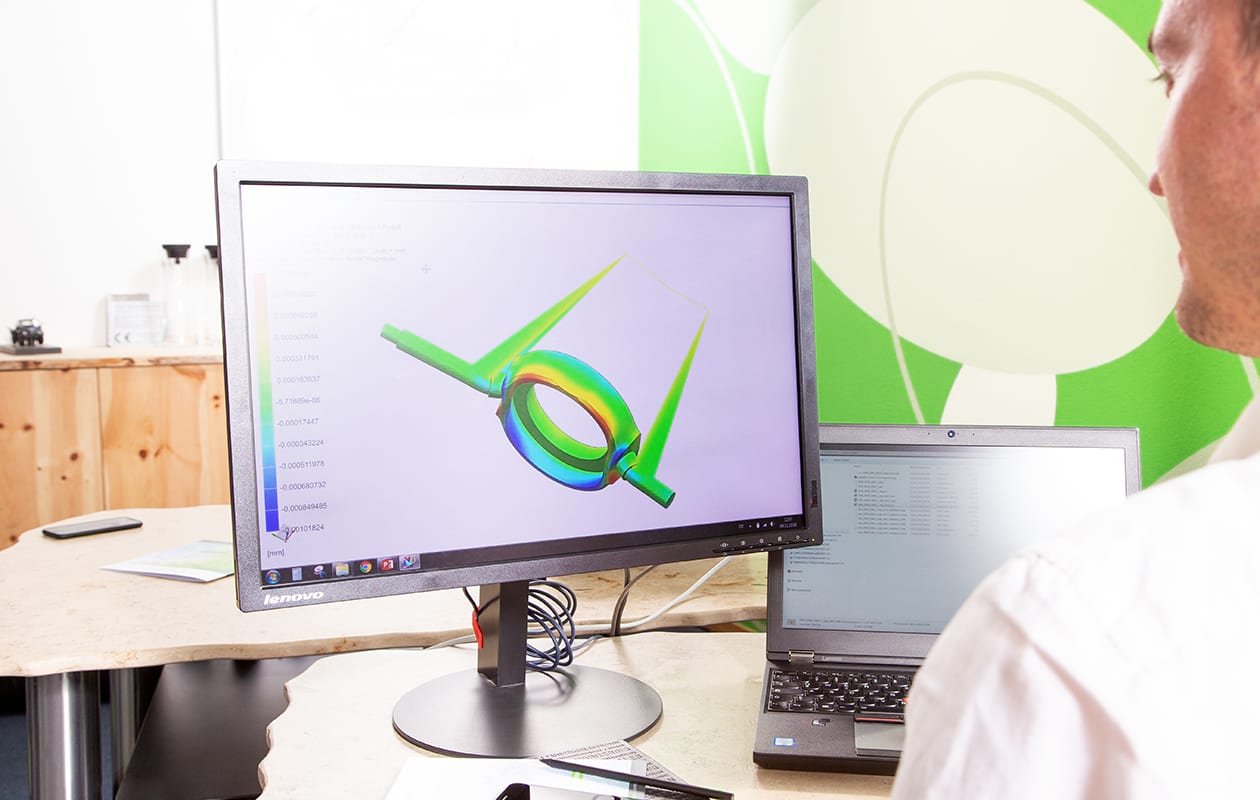

SIMULATION, COMPUTATION, DMU ASSEMBLY SPACE INSPECTION

Alongside your project, our engineering experts calculate the stability and oscillation of your components and assemblies. At the same time, we inspect the digital installation and removal, as well as testing the collision and packaging.

Thanks to small but significant changes to the design, we ensure the buildability for you and make sure that the components are optimally conceived – throughout the entire product development process

TEST BED ADAPTATION

Our experts design and construct bespoke adaptation units and modules for your existing testing systems and integrate them for you. This saves you time and money. For example, they reduce the set-up time and trial new test items without much effort. This means you can make your testing workflow more flexible.

Example projects:

- Adaptations for the passive safety trolley system for motor test beds

- Testing stands

- Test item holder

- Set-up parts

DIGITAL TWIN AND VIRTUAL REALITY (VR)/AUGMENTED REALITY (AR)

Our experts virtually disassemble real machines or plants using a digital twin throughout the entire operating life. This means we are at your products’ side from the initial concept throughout the full, optimized life cycle.

Sensors on your machines continuously send data and information to the virtual clone. The digital twin is thus constantly learning – for example, to react independently and to counteract or correct faults. This helps us to optimize your plant design and reduce your changeover times. You can operate your machine even more efficiently, without faults – and take future products to an even higher quality level.

At the same time, our experts develop

analysis and interaction models for you with the digital twin, which you can

test with all conventional output media. For example, you can explore different

test parameters under virtual conditions to deduce important information for

your real products. You can realistically observe a product using an

interaction model during a VR session. The time and place is therefore

irrelevant. Alternatively, you can use an augmented reality (AR) or 3D scan to

integrate the digital twin into real conditions and uncover valuable findings.

SERVICE & MAINTENANCE

Our engineering experts will also advise you in after-sales: they analyze your machines and plants and proactively maintain them in order to keep downtimes low or to prevent them altogether. Key word: predictive maintenance. You can therefore increase the service life of your machines and save on costs.

Would you like to carry out your own service and maintenance work? Our experts will also be happy to help you with this and offer you practical instructions and documentation.

TRADE FAIR EXHIBITS

Our experts will set the stage for your perfect trade fair presentation. They design exhibits that match your targets and wishes to a tee.

Whether you need a simple stall or a complex construction: our specialists use cutting-edge 3D CAD software to design your exhibit before they produce it, assemble it, switch everything on and put it through its paces.

You get affordable exhibits within no time at all, and your visitors get to be stunned by your impressive presentation.

Other services

- You have not yet bookmarked any products.

- You have not yet bookmarked any products.